LINEA MICHELANGELO – TAB Servo turrets

TAB is a vertical axis turret with bi-directional positioning, no body lifting during the indexing rotation, really simple design, really high performances and request a minimum maintenance.

They use a fully hydraulic locking system and rotate thanks to a BRUSHLESS SERVO MOTOR controlled by a SERVO DRIVE.

Turrets can carry 4/6 tool holders as per DIN 69881 norms; on demand, they can be supplied with a different number of faces or special body.

TAB turrets can be mounted with the axis in horizontal, slanting position.

CHARATERISTICS

• Very high rotation speed with minimum indexing times

• Bi-directional

• Locking and Unlocking without body lifting

• Double sensor for locking and unlocking status

• High rigidity due to the new design

• Possibility to use turret body with 4 or 6 positions.

• Possibility to lock the turret in intermediate positions (24 divisions)

• Coolant output flow through valve on the body side

• Possibility, upon request, to increase the coolant pressure up to 70 bar

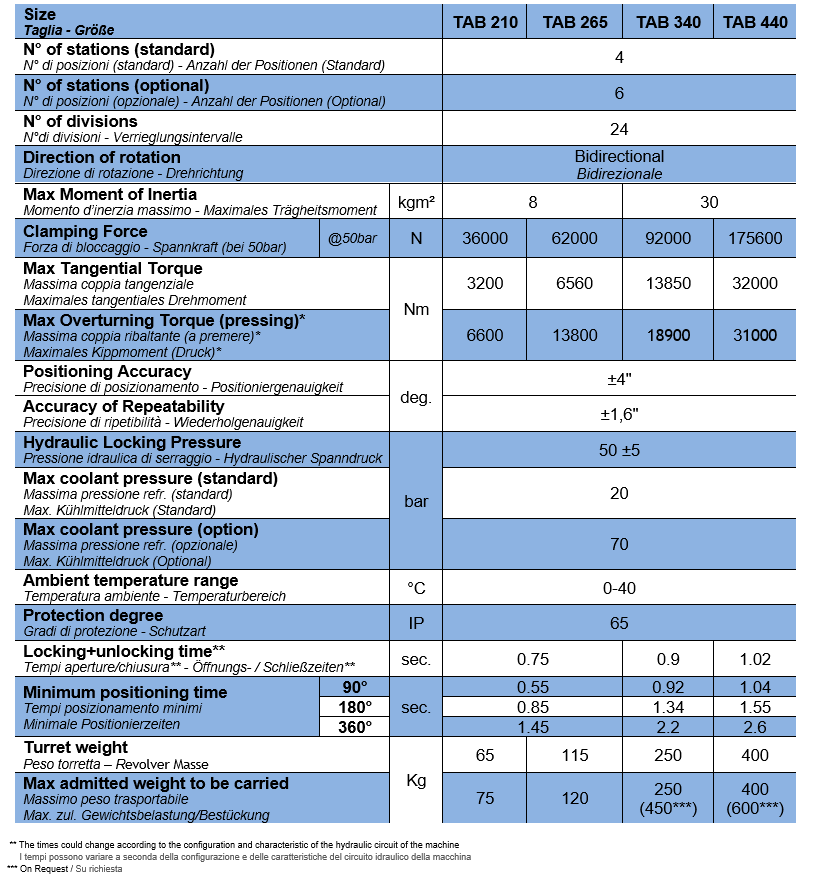

TECHNCIAL DATA

FUNCTION DESCRIPTION

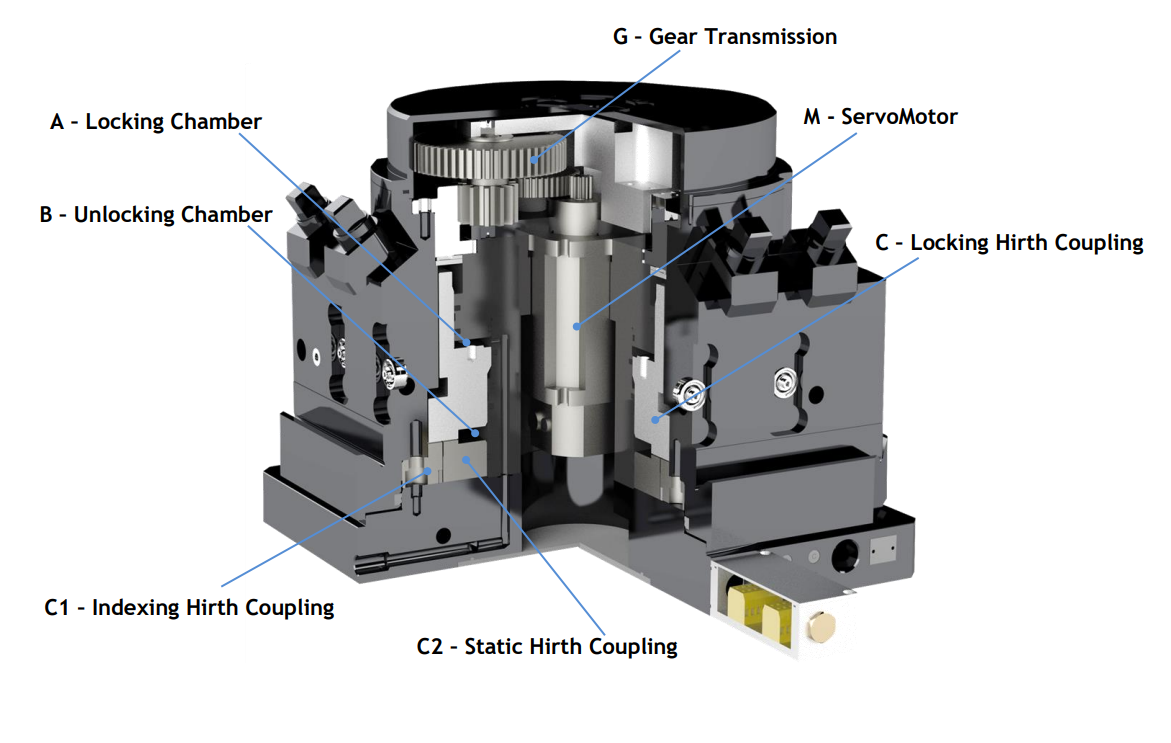

The turret rotates and positions thanks to an internal Brushless Servo Motor (M) fully controlled by our safe and stable Servo Drive type DMS08.

When hydraulic oil pressure acts in chamber (B), locking ring (C) moves upwards, disengaging hirth teeth rings. The turret is thus ready for tool change.

During turret locking sequence, oil pressure acts in chamber (A) and pushes locking ring (C) downward, making hirth teeth rings engage. The turret is ready for machining. Motor (M) drives tool holder body by means of a gear transmission, to achieve tool change.

The turret is equipped with safety springs that push locking ring (C) downward when oil pressure is close to zero. This is only a security self-locking in the event of an oil pressure breakdown (for instance due to power failure).

Download catalog