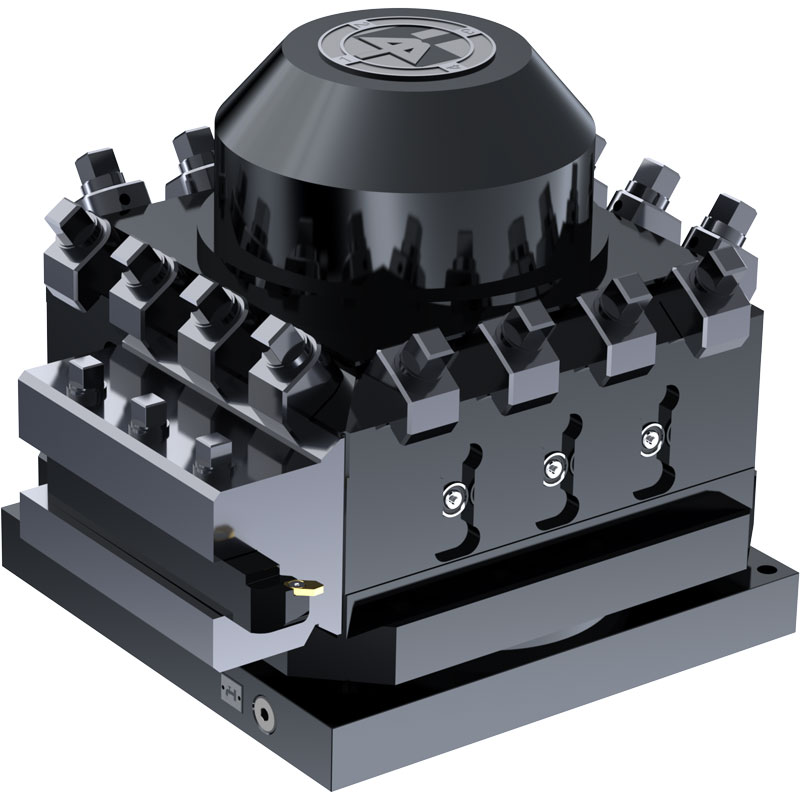

TAN – Electromechanical turrets with vertical axis

TAN series turrets consist of a fixed basis and a rotating head both of hardened and grinded steel.

Thanks to an innovative electromechanical system a single motor controls the phases of release, of rotation of positioning and locking.

These turrets can be mounted with the axis in horizontal, vertical or slanting position.

It is possible forthermore to select any work station without necessity of stopping in the intermediate stations.

Turrets are normally built for carryng 4 tools as per DIN norms 3425; on demand they can be supplied with a different number of face s and every fce is supplied with a slot for the positioning of the tools (presetting), solution which allows to reduce tha dead times necessary for the presetting of the tools.

| Size |

160 |

440 |

||

| Number of stations |

4 |

4-6-8 |

||

| Moment of inertia | Kgm² |

1 |

55 |

|

| Max tangential torque |

Nm |

1500 | 26100 | |

| Tilting torque in pressing direction * |

1620 |

38500 |

||

| Tilting torque in lifting direction* |

935 |

17650 |

||

| *Distance from the turret axis |

mm |

180 |

450 |

|

| Unbalancing torque on horizontal axis |

Nm |

8 | 400 | |

| Positioning accuracy |

Deg. |

± 5” | ||

| Positioning repeatability |

± 1,8” |

|||

| Unlocking time |

Sec |

0,28 |

0,80 |

|

| Rotation time (360°) |

1,66 |

10 |

||

| Lockingtime |

|

0,82 |

1,6 |

|

| Indexing frequency |

n°/h |

600 |

200 | |

| Max Coolant Pressure |

Bar |

10 |

||

| Eyebolt hole dimension |

M10 |

M24 |

||

| Max weight to be carried |

Kg |

35 |

320 |

|

| Turret weight (without tools) |

31 |

430 |

||

| Environment temperature range |

°C |

+5 /+40 |

||